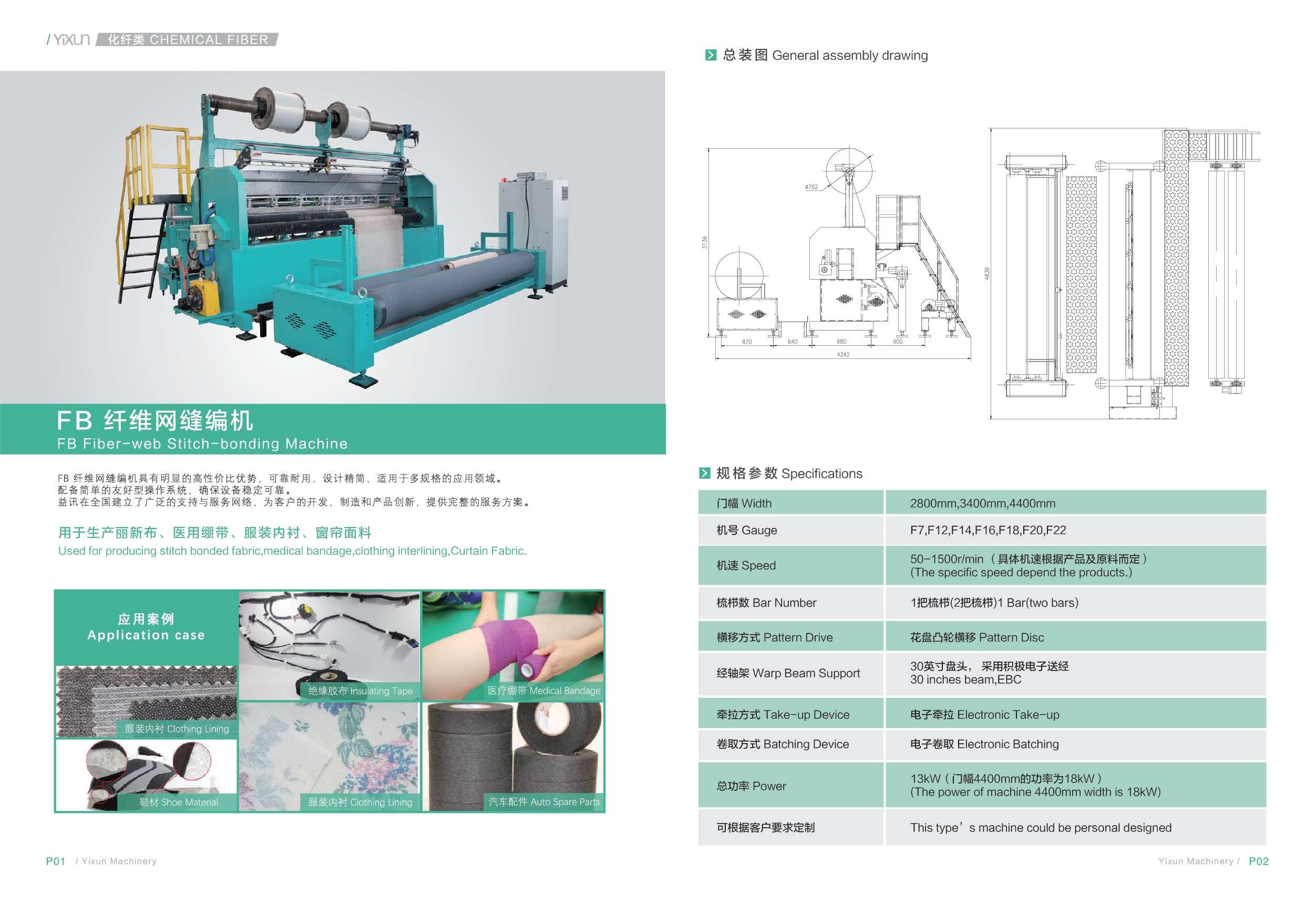

Stitch-Bonding Machine

| Category | Machines |

| Model No. | VS-MWT1 |

| Place of Origin | Fujian,China (Mainland) |

| Certification | CE |

| Package | Wooden Cases |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

VS-MWT1

Stitch-Bonding Machine

- For the nonwoven processing which widely applied inin technical textile

- (e.g. Automotive, Filtration, Shoe, Coating etc)

- Gauge 14-22 F Working width: 3600m.

Operating conditions

- The manufacturer’s prescribed ambient temperature for the machine is 25 degrees Celsius (+/-2 degrees Celsius). at 65 % relative air humidity.

- Draft has to be avoided. The machine has to be protected against dust and fibre fly.

- The floor load lies between 2000 and 4500 kg/square meter, depending on the relevant machine type and machine length. Operational vibrations have to be

- taken into account when installing the machine.

- The manufacturer has to be informed about other operating conditions than those specified above. In this case, specialagreements have to be concluded with the manufacturer.

Bars/knitting elements

Compound needle bar, closing wire bar, knock over sinker bar, supporting bar, counter retaining bar, 1 ground guide bars

Pattern drive-N

N-drive with pattern disc, integrated tempi change gear drive, 1 pattern disks

Warp beam support(1×30″)

1 warp beam position for sectional of max 30 flange diameter.

Yarn let-off device

For each completely mounted warp beam position:1 electronically controlled yarn let-off drive, driven by geared motor and frequency converter.

Yam stop motion(optional)

Electronically controlled

Fabric take-up

Electronically controlled fabric take-up, driven by geared motor and frequency converter.

Batching device standing separately

With friction drive by pressure roller, max batch diameter of 914 mm (36 inches), driven by geared motor with integrated frequency converter, control to match the stitch courses.

Motion Control

Machine control computer for the control of the basic functions such as main drive, yarn feeding and fabric take-up.

Operator Interface

Touch screen in the switch cabinet for production data display.

Electrical equipment for three-phase current

Speed-regulated drive, power-failure safe, including inching motion function. Single speed for the control of the basic functions frequency converter KW, main motor 7.5 KW

Frequency

Frequency 50 cycles

Oil supply

Immersion lubrication in the crank-case with filter

Download:

FB-3400-Stitch-Bonding-Machine