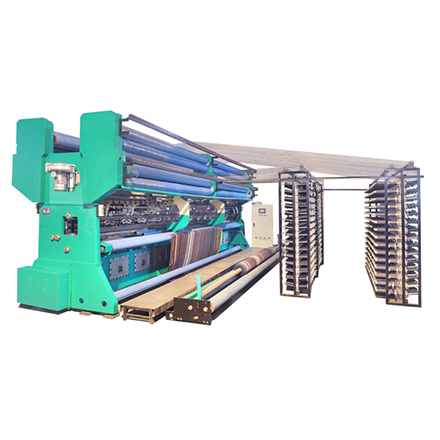

GS-RS6-NET-Z Open Cam-Tongue Needle

| Category | Raschel Machine | Net machines |

| Model No. | GS-RS6-NET |

| Place of Origin | Fujian,China (Mainland) |

| Certification | CE |

| Package | Wooden Cases |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

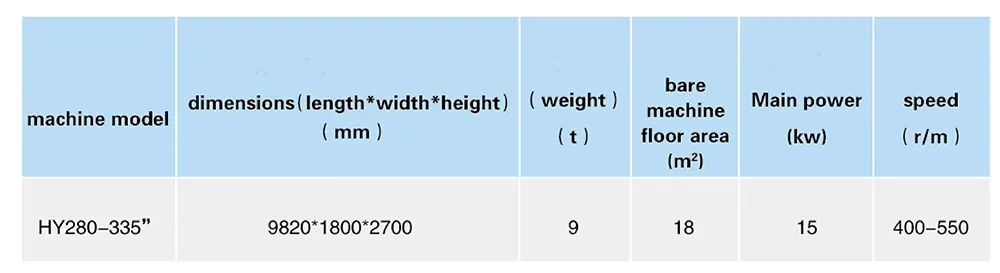

Technical data:

Working width & Gauge

- Type: Latch needles (the needle can be mounted on bed in block or inserting separately)

- Gauge: E1, E3, E6, E8, E10, E12

- Width:181″, 205″, 268″, 283″, 335″, 413″, 503″

Bars / knitting elements:

- Single-needle bar, knockover comb bar and slider bar, stitch comb bar

- Bars Number: 6 (Other type can be: 2, 3, 4, 5, 6, 8)

Yarn Feeding Systems:

- WARP BEAM SUPPORT : 4 warp beam positions, free-standing, for working from sectional beams with a flange diameter of 812 mm (32”) Yarn let-off device electronically controlled, driven by geared motor.

- YARN FEEDING DEVICES: 3 or 4 yarn feeding device positions with 3 driven feeding rollers each, for working from a creel

- FTL: Film cutting and stretching device for working with primary film

GrandStar®(GrandStar COMMAND SYSTEM): Operator interface to configure, control and adjust the electronic functionality of the machine

Integrated monitoring systems: Integrated Laserstop

Yarn Iet-off device: Mechanical negative Let-off gear.

Fabric take-up: Mechanical regulated, system with friction drive, driven servomotor, controlled via Motion Control.

Batching device: Separate floor-standing cloth rolling device

Pattern drive: n-drive with 6 pattern discs, integrated tempi change gear.

Electrical equipment

- Speed-regulated drive, total connected load of the machine: 25 kVA

- Voltage: 380V±10% three-phase power supply, main power cord requirements: not less than 4m㎡ three-phase four-core power cord, ground wire not less than 6m㎡

Oil supply: None

Equipment working conditions

- Temperature 25℃±6℃, humidity 65%±10%

- Floor pressure: 2000-4000KG/㎡