Tricot machines with 4 guide bars GS-HKS4-M

| Category | Tricot Machine |

| Model No. | GS-HKS4-M |

| Place of Origin | Fujian,China (Mainland) |

| Certification | CE |

| Package | Wooden Cases |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

Bars / knitting elements:

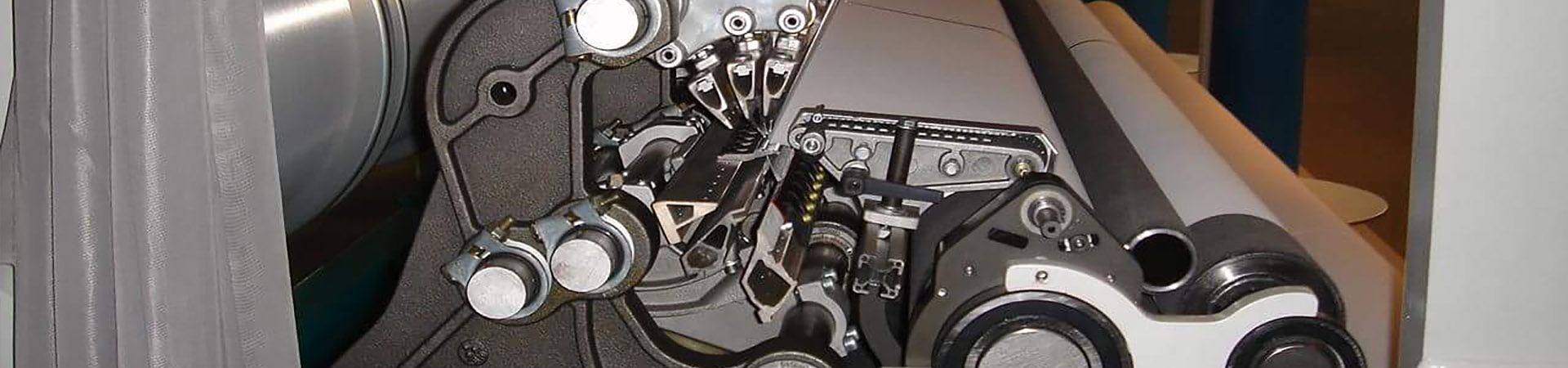

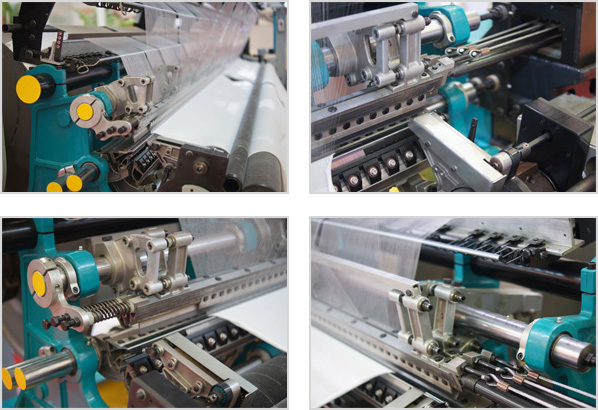

Individual needle bar with compound needles, slider bar with plate slider units (½”), sinker bar with compound sinker units, two guide bars with guide units. All bars are made of carbon-fibre-reinforced material.

Warp beam support:

- 4 × 812 (32″) (free-standing)

- Option: 4 × 1016 (40″) (free-standing)

GrandStar®(GrandStar COMMAND SYSTEM): Operator interface to configure, control and adjust the electronic functionality of the machine

Integrated monitoring systems

- Integrated Laserstop

- Integrated camera

Yarn Iet-off device: For each completely mounted warp beam position: one electronically controlled yarn Iet-off drive

Fabric take-up: Electronically regulated fabric take-up, driven by geared motor, consisting of four rollers.

Batching device: Separate floor-standing cloth rolling device

Pattern drive

- Electronic guide bar drive EL, all guide bars shog up to 50 mm

- Optional increased shog distance (up to): 150 mm

Electrical equipment

- Speed-regulated drive, total connected load of the machine: 25 kVA

- Voltage: 380V±10% three-phase power supply, main power cord requirements: not less than 4m㎡ three-phase four-core power cord, ground wire not less than 6m㎡

Oil supply: oil/water heat Exchanger

Equipment working conditions

- Temperature 25℃±6℃, humidity 65%±10%

- Floor pressure: 2000-4000KG/㎡

Working width: 4724mm(186″):5537mm(218″):5791mm(228″)

Gauge: E28、E32

|

Working width |

FH-HKS2-S |

|

|

gauge from |

to |

|

|

130″ (+ 2″ working width extension for rigid fabrics)(+ 4″ working width extension forelastic fabrics) |

E 40 |

E40 |

|

180″ (+ 6″ working width extension) |

E 28 |

E 36 |

|

210″ (+ 8″ working width extension) |

E 28 |

E 36 |